Effective Use of Siphon Pits in High-Tech Intensive and Super-Intensive White-Leg Shrimp Farming

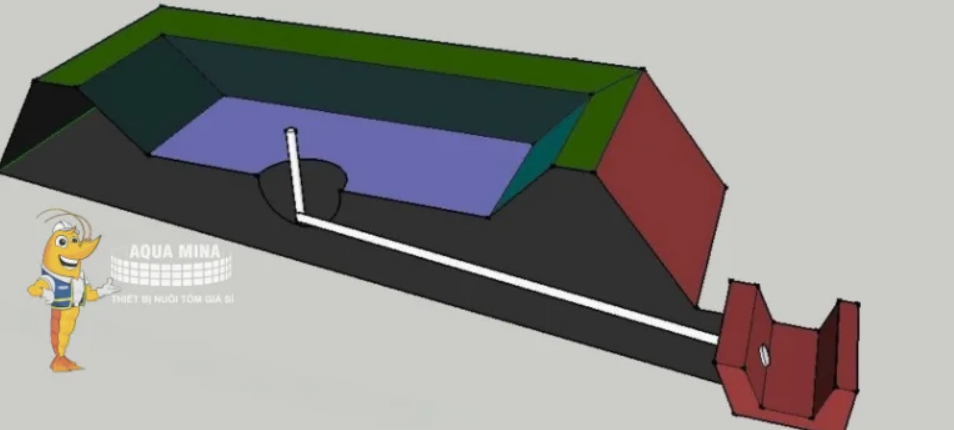

With such pond designs, waste is directed into a central siphon pit, which is typically conical in shape and wide enough to collect organic matter. The diameter of the pit opening usually ranges from 30 to 50 cm, depending on the pond size, and the vertical distance from the pit opening to the bottom is about 40–50 cm.

Organic Waste Accumulation Leads to Toxic Conditions

As farming progresses, the accumulation of organic matter in the siphon pit increases with shrimp biomass, feed frequency, and density. Under high temperatures and strong sunlight, the rate of decomposition intensifies—consuming dissolved oxygen and releasing toxic gases such as ammonia (NH₃), hydrogen sulfide (H₂S), and nitrite (NO₂).

These gases can severely stress shrimp, especially when pond pH exceeds 8.2. From 11 a.m. to 4 p.m., when pH tends to rise, more NH₃ is generated, fueling the natural nitrogen cycle and increasing NO₂ levels.

When NH₃ exceeds 0.1 mg/L and NO₂ exceeds 0.02 mg/L, shrimp exhibit abnormal behavior—swimming at the surface, along pond edges, or surfacing in the early morning or late afternoon. NO₂ binds with hemocyanin in shrimp blood to form methemoglobin, which reduces oxygen transport, causing hypoxia.

As a result, shrimp reduce feed intake or stop eating, molting becomes difficult or incomplete, shells stay soft, growth slows, and dead shrimp may be found at the siphon pit—sometimes with only the muscle (meat) left behind.

Low Salinity Exacerbates the Issue

In low-salinity environments, osmotic pressure imbalances between shrimp and water further complicate molting. The competition between NO₂⁻ and Cl⁻ ions hinders molting and shell hardening, leading to stress, vulnerability to external parasites and bacteria, gill damage, and mass mortality.

Proper Siphon Design and Operation Are Critical

Siphon pits must be well-designed and used consistently in intensive shrimp farming systems. The frequency, timing, and duration of siphoning—and the farmer's experience—greatly affect water quality.

In the first month, organic waste is still low. Siphoning once or twice daily for 1–1.5 hours is sufficient to remove waste in and around the pit.

From the second month onward, organic matter builds up rapidly throughout the day. Siphoning should be increased to 3–4 times/day, each lasting 2–2.5 hours, ideally 30–60 minutes after feeding.

For high-density systems, installing automatic siphon systems is highly recommended.

Proactive Waste Removal = Healthy Shrimp + Cost Savings

Regular and proactive siphoning helps prevent toxic gas accumulation and disease outbreaks. This not only reduces the need for medication but also creates a clean environment for faster growth, better survival rates, and improved feed conversion ratio (FCR).

Source: Tép Bạc

Aqua Mina's distributor in Japan: REX INDUSTRIES CO., LTD

- Address: 1-9-3 Hishiya-Higashi, Higashi-Osaka 578-0948 JAPAN

- Email: kimakubo@rexind.co.jp

- Phone: +81-(0)72-961-9893

- Website: http://www.rexind.co.jp/e/

WE WORK FOR YOUR SUCCESS!

Ngày đăng : 25/04/2025

2335 View

Other Articles

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)