Cost-Effective Implementation of An Industrial Shrimp Farming Model

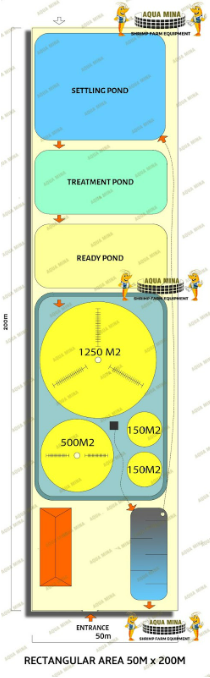

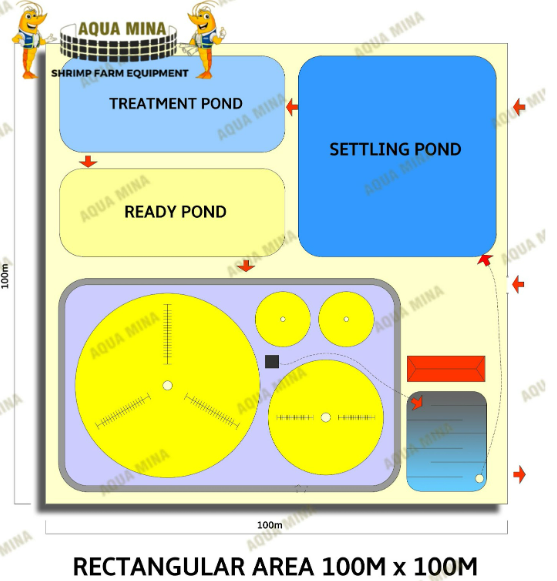

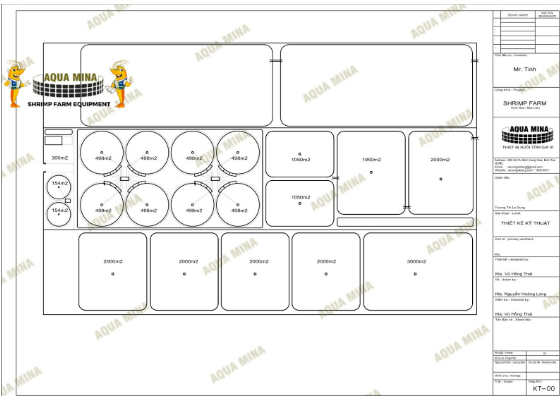

For many shrimp farmers today, establishing an industrial shrimp farming facility presents a challenging initial investment. Considering shrimp farming practices and limited land resources, AQUA MINA's architects have researched and proposed an optimized investment model for a family of 4 people in the Mekong Delta, covering just 1 hectare.

This includes:

- - 2 mobile round tanks for nursing 150m² with alternating water treatment.

- - 1 tank for the shrimp at phase 2, covering 500m².

- - 1 tank for the shrimp at phase 3, ranging from 1000m² to 1200m².

- - 1 water storage tank, 1 settling tank, 1 treatment tank, and 1 waste treatment tank post-farming.

- - 1 residential house + warehouse, centralized location for material storage and harvesting.

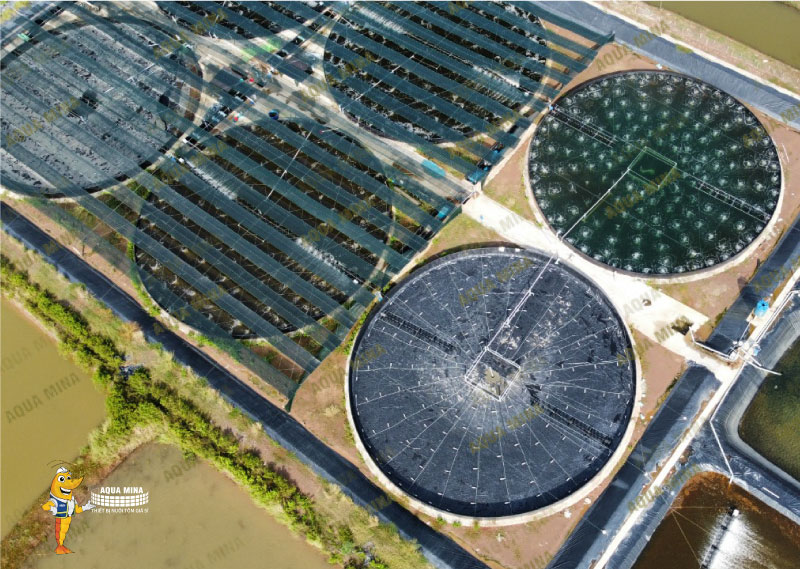

- The project offers two land layout options: 50x200m and 100x100m. Tanks are positioned near the residential area and feature independent rain roofs, ensuring effective farming conditions.

- The farming area using white plastic wire helps reduce the exposure to sunlight, wind, prevents bird interference, and safeguards against theft.

- The settling tank is earthen , while the treatment tanks are equipped to be HDPE lined, ensuring water undergoes treatment before being pumped into the farming area.

In this approach, the transition to phase 2 occurs for shrimp after approximately 20-25 days in the initial nursery stage. Following an additional 30 days, the shrimp are transferred to phase 3 to continue their growth. Meanwhile, the mobile round tanks are readied with fresh nursery shrimp, prepared for the subsequent rotation.

Using this method, farmers can harvest shrimp once every 2 months, maintaining a steady cash flow without needing to make frequent material purchases that might drive up costs. Additionally, the workload is distributed evenly each month, reducing the need to hire workers for periodic tank cleaning or harvesting.

Consequently, this approach decreases external labor expenses significantly. The above is a simple and effective practice that many individuals have adopted. For further information, kindly provide your details, and our AQUA MINA project team will offer free consultation for your needs.

Contact AQUA MINA for consultation and to acquire mobile round tanks to enhance your agricultural production efficiently.

AQUA MINA CO. LTD

- Address: 685 Highway 1A, Quarter 4, Binh Hung Hoa Ward, Binh Tan District, Ho Chi Minh City.

- Website: aquamina.com.vn

- Hotline: 1800 6071 (toll-free)

- Email: sales@aquamina.com.vn or oversea@aquamina.com.vn

WE WORK FOR YOUR SUCCESS!

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)