FACTORS AFFECTING SHRIMP PRICES

1. First Factor:

Antibiotic residues in farmed shrimp. Since most farmers use antibiotics in shrimp farming, the residual levels when harvesting shrimp are very high (with contamination levels above 30%). Meanwhile, major and potential export markets like the U.S., Japan, and Europe strictly control this issue.

2. Second Factor:

Shrimp color. Currently, import markets place high importance on shrimp color. They prefer shrimp that turn red when boiled, while shrimp products from Vietnam mostly turn pale pink or white after boiling, making it difficult to meet customer demands. This reduces the competitiveness of Vietnamese shrimp compared to shrimp from other countries. Some countries use Astaxanthin mixed into feed to enhance shrimp color, or employ farming processes that cultivate algae to create a darker gray color in harvested shrimp.

3. Third Factor:

Shrimp size at harvest. Farmers usually harvest shrimp at sizes ranging from 30-50 shrimp per kilogram. This farming practice results in slower growth and reduces the market competitiveness of the product, as the supply does not align with market demand. Currently, most markets have a strong demand for shrimp sizes of 50-70 shrimp per kilogram (especially the European and Japanese markets). Therefore, farming shrimp to a single size makes it difficult to compete and find customers.

4. Fourth Factor:

Other factors influencing shrimp prices include: geographic regions unsuitable for aquaculture, irregular farming seasons prone to disease outbreaks, consumer demand during holidays and festivals, natural disasters causing crop failures, and fluctuations in the international market.

* SOLUTIONS TO INCREASE EFFICIENCY IN SHRIMP FARMING

1. Four Clean Principles:

- Disease-free shrimp seeds

- Clean water sources for farming

- Antibiotic-free: Enhances product competitiveness in the market, enabling shrimp to be sold at higher prices and ensuring stable and sustainable development.

- Clean environment

Shrimp farming water is sourced from the sea with salinity levels of 25‰ or higher, and the water is reused through a natural filtration system combined with membrane filters. Siphoned sludge from the pond bottom is treated with biogas, and the final sludge is used to raise black soldier flies for shrimp feed or to produce protein powder for shrimp and livestock feed.

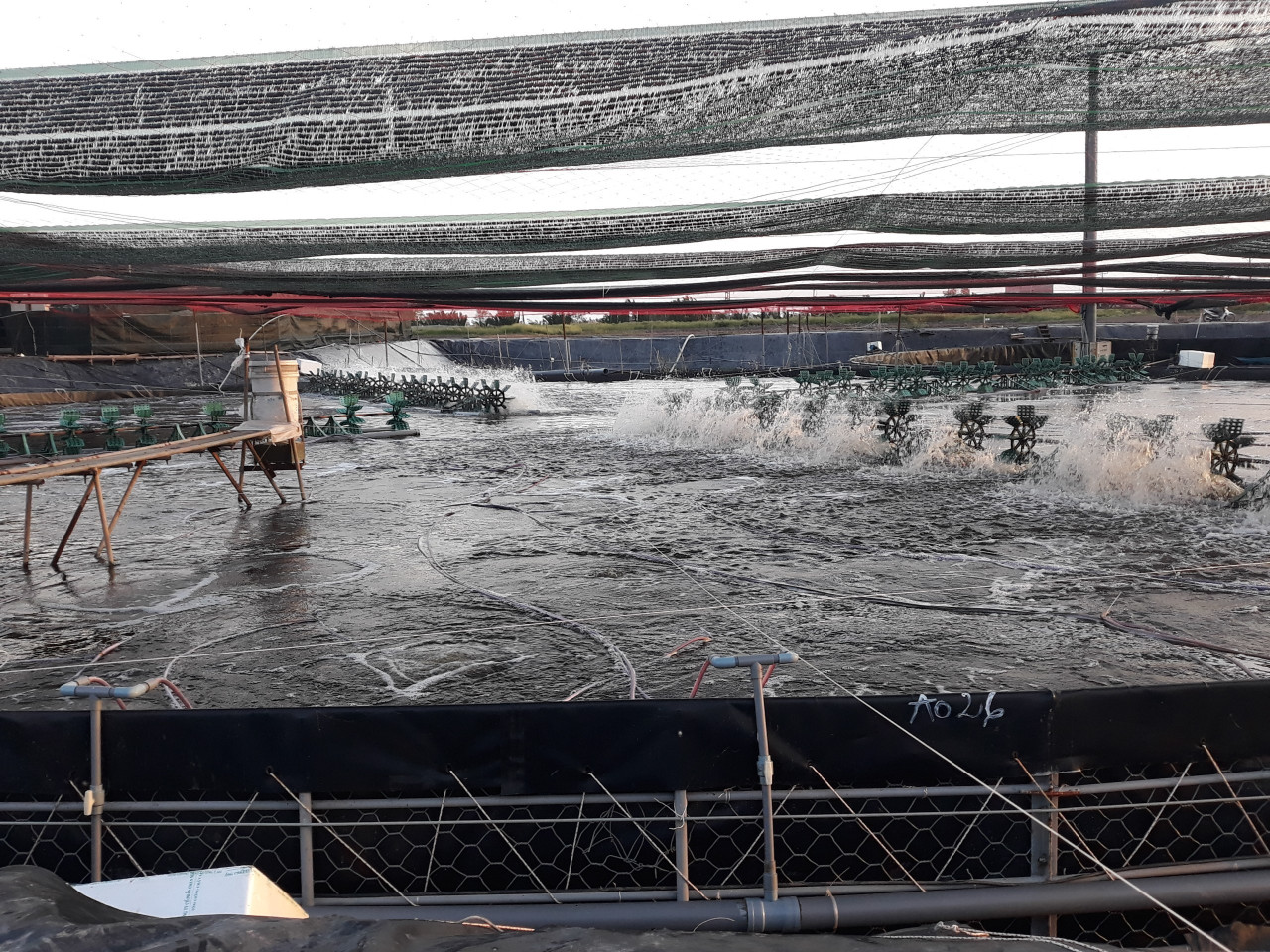

2. Two-Stage Shrimp Farming:

Switching to two-stage shrimp farming instead of the traditional single-stage farming reduces risks and fosters shrimp growth. AQUA MINA Company has participated in the Agricultural and Aquatic Processing Exhibition with its mobile nursery ponds, which have garnered significant attention, especially from provincial agricultural extension centers across the country. This two-stage farming method has been effectively implemented by farmers.

- Stage 1: Shrimp are raised in a nursery pond with a diameter of about 10 meters for 25-30 days, allowing close care of the young shrimp and creating optimal conditions for strong development from the start.

- Stage 2: After selecting healthy shrimp in the first stage, they are transferred to a grow-out pond with a diameter of 32 meters for 70-80 days to boost growth.

3. Three-Tier Harvesting:

- First Harvest: At 60-65 days old, 50% of the shrimp in the pond are harvested, with an average weight of 65-70 shrimp per kilogram.

- Second Harvest: At 80-85 days old, another 50% of the shrimp are harvested, with an average weight of 40-45 shrimp per kilogram.

- Third Harvest: The remaining shrimp in the pond are harvested at 110-115 days old, with an average weight of 15-20 shrimp per kilogram.

Ngày đăng : 03/09/2024

1414 View

Other Articles

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)