Biosecurity – The Key Solution to Aquatic Animal Disease Challenges

Biosecurity Becomes a Key Factor in Aquaculture

Challenges in Aquaculture (AqF)

Aquaculture is an important economic sector, providing food resources and contributing to national livelihoods. However, the industry is facing serious challenges, especially disease outbreaks and environmental pollution. These issues not only cause economic losses but also impact food safety and long-term sustainability.

In recent years, persistent shrimp diseases such as White Spot Syndrome Virus (WSSV), Acute Hepatopancreatic Necrosis Disease (AHPND/EMS), and White Feces Disease have remained major concerns for shrimp farmers.

At the beginning of the 2025 shrimp farming season, infection rates of TPD and EHP were extremely high, causing severe losses for farmers. TPD and EHP have caused significant damage to the shrimp industry, yet no definitive treatment is available for either disease. Given this situation, biosecurity (BHS) has become a decisive factor for farming success. Close monitoring, proper care, and maintaining a stable environment are essential keys to reducing disease-related losses.

The Importance of Biosecurity (BHS)

Biosecurity involves following strict management measures to prevent the entry of specific pathogens into the system or reduce pathogen loads, thereby preventing animals from becoming infected or exposed to infectious agents and parasites. Quarantine, sanitation, and disinfection are all essential elements of BHS.

Proper application of biosecurity measures provides many long-term benefits:

Reducing Disease Risks

Biosecurity helps prevent the introduction and spread of dangerous pathogens such as:

White Spot Syndrome Virus (WSSV),

Acute Hepatopancreatic Necrosis Disease (AHPND),

Bacterial diseases like Streptococcosis in fish.

It also reduces dependence on antibiotics, limiting drug resistance and environmental contamination.

Increasing Productivity and Product Quality

Healthy shrimp and fish have stable and higher growth rates.

Biosecurity helps produce clean, chemical-free products that meet food safety standards, strengthening competitiveness in export markets.

Protecting the Environment and Ecosystems

BHS helps minimize water pollution caused by disease outbreaks and farm waste, reducing risks of pathogen spread to natural ecosystems.

It ecourages the use of biological products instead of chemicals to maintain ecological balance.

Meeting Market and Export Requirements

Major markets such as the EU, the U.S., and Japan require strict compliance with biosecurity standards.

Proper BHS enhances product value and expands export opportunities.

Improving Economic Efficiency and Reducing Production Costs

Effective BHS reduces losses from disease outbreaks, treatment costs, and the need to replace stock.

It optimizes farming procedures, reduces mortality, and increases profits—supporting long-term sustainable development.

Disinfectants: A Key Element of Biosecurity Strategies

Effective and safe disinfectants are essential to any biosecurity program in aquaculture.

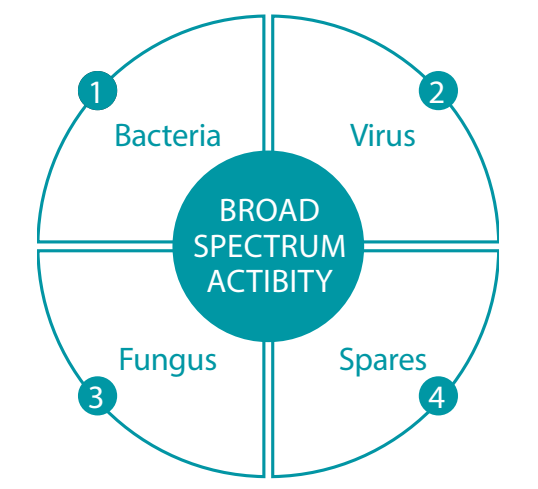

Disinfectants are used to reduce disease transmission risks and control harmful agents such as viruses, bacteria, and fungi in shrimp and fish farming.

Biosecurity programs depend heavily on the effectiveness of disinfectants under various conditions (organic load, salinity, temperature…) while ensuring safety for workers and aquatic animals.

NADIS – Broad-Spectrum Disinfectant for Aquaculture

With main components including Potassium Monopersulfate, salts, buffers, organic acids, detergents, and stabilizers, Nadis is a broad-spectrum disinfectant designed to support BHS in aquaculture.

When Nadis dissolves in water, it triggers a series of chemical reactions that create a synergistic blend of six powerful disinfecting agents. These agents inactivate pathogens by breaking sulfur bonds in proteins and DNA, causing irreversible cell membrane damage and disrupting cellular metabolism.

Nadis is 100% biodegradable, making it ideal for aquaculture, equipment sanitation, tank disinfection, and water treatment.

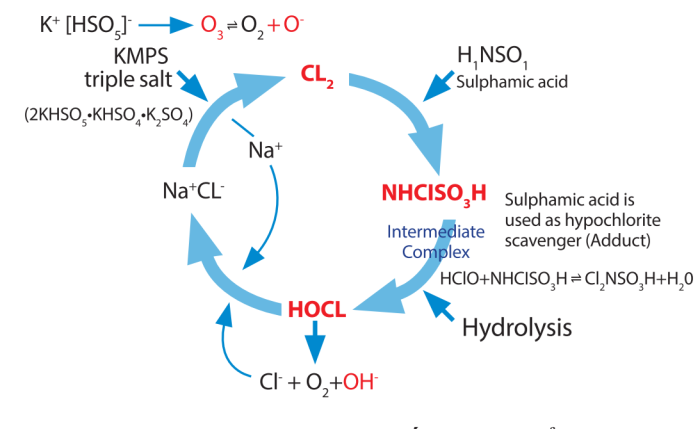

Six Disinfectant Compounds Generated by Nadis – Mechanism of Action

Sodium chloride is oxidized by Potassium Monopersulfate (KMPS), releasing free chlorine (Cl₂).

KPS also generates ozone (O₃) when dissolved in water; ozone quickly dissociates into atomic oxygen (O⁻).

Free chlorine reacts with sulfonic acid to form an intermediate complex that hydrolyzes to release hypochlorous acid (HOCl), which then forms hydroxyl ions (OH⁻).

Released chloride contributes to forming additional sodium chloride, supplying fuel for repeated reaction cycles.

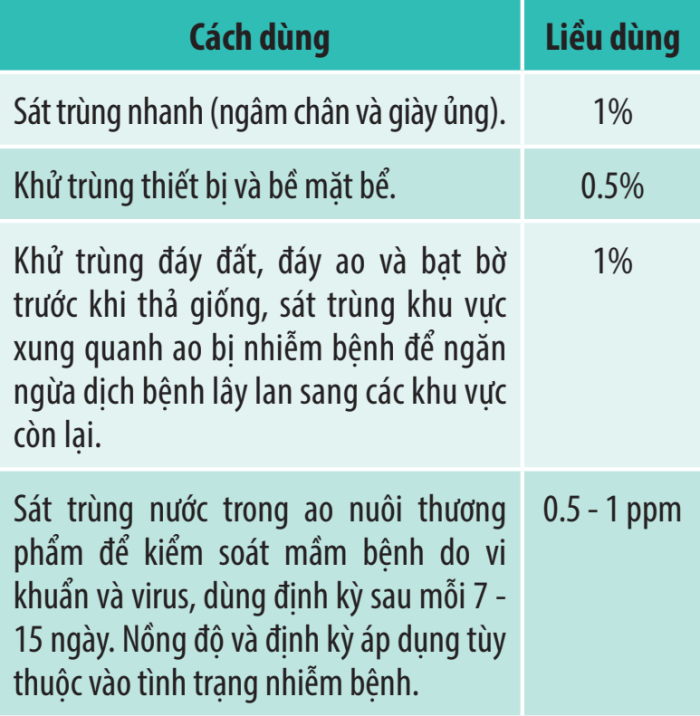

Usage Instructions

Dilute Nadis to 1% concentration before use (equivalent to 1 kg per 100 liters of water).

Disinfectants are an important tool in aquaculture biosecurity. However, for optimal effectiveness and minimal environmental or animal health impacts, it is essential to select the right product, apply proper dosage, and integrate it with other management strategies.

AQUA MINA CO., LTD

– Address: 685 Le Duc Anh Street, Quarter 39, Binh Hung Hoa Ward, Ho Chi Minh City

– Phone: 1800 6071 (Toll-free hotline)

– Email: sales@aquamina.com.vn or oversea@aquamina.com.vn

– Aqua Mina’s Official Distributor in Japan: REX INDUSTRIES CO., LTD

– Address: 1-9-3 Hishiya-Higashi, Higashi-Osaka 578-0948, JAPAN

– Email: kimakubo@rexind.co.jp

– Phone: +81-(0)72-961-9893

– Website: www.rexind.co.jp/e/

WE WORK FOR THE SUCCESS

Ngày đăng : 21/11/2025

1671 View

Other Articles

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)