How to handle when running a fan system that creates insoluble white foam in aquaculture

For shrimp ponds, running fans plays a role in providing the necessary amount of oxygen for shrimp. But if when running the fan, white foam appears that takes a long time or does not dissolve, then what are they and are they harmful to shrimps? Let's find out with Tommy in the article below!

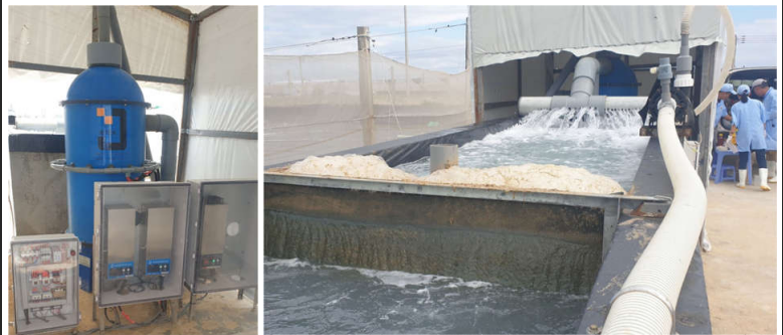

The phenomenon of white foam dissolving for a long time or not dissolving at all

During the process of running the pond fan, a lot of long-lasting white foam often appears on the pond surface. This is a sign that the pond water has a lot of suspended sediment such as dead algae, organic matter from leftover feed, algae, filamentous bacteria, and other suspended solid particles. Foam can be white, light brown, or green depending on the agent causing the foam. Except when foam appears due to the use of chemicals with foaming agents such as detergents or saponins, after using BKC.

If left untreated, white foam will appear more and more. When white foam appears, it is a sign of polluted pond water quality due to large amounts of organic matter (shrimp feces, leftover feed). In addition, very high levels of toxic gases (NH3 and NO2) are appearing in the pond.

Distinguishing different types of foam

- The type that dissolves quickly, does not affect the environment or shrimp ponds: is the type of foam created by aeration devices or by fan operations that dissolve oxygen into the water, creating it right on the flow and quickly dissolving immediately after that or the strips of bubbles do not last long and move around the pond. This type of foam usually dissolves very quickly and is white.

- Foam formed due to chemical use: Normally, chemicals used in shrimp ponds always create foam when applied. In addition to creating foam, they also create a different surface tension of pond water at the time of application. At the point of using chemicals, this phenomenon is easy to observe the change in water surface state when using chemicals.

- This type of foam dissolves quickly or slowly depending on the type of chemical used and the dosage used. However, they will dissolve after 1-2 hours. Saponin is also the active ingredient that creates foam when used: Using saponin to kill impurities or stimulate peeling (not recommended) also creates foam, because the active ingredient saponin has soapy properties.

- Colored foam, detrimental to the environment and farmed shrimp: This type of foam usually takes a long time to dissolve and often has a characteristic color of brown or black from light to dark. There are many causes of this foam such as sudden algae collapse, excess feeding, lots of shrimp feces due to not siphoning well...

- Permanent colored foam is a collection of suspended or unwanted organic matter. Their existence is an indicator of water quality - the living environment for shrimps is gradually deteriorating. It can be compared to the way we live in surroundings whose quality does not really make us comfortable.

Causes of white foam formation

Formation of toxic H2S gas in shrimp ponds: The process of raising shrimps in ponds will gradually produce organic substances in the water such as: shrimp feces, leftover feed, etc. The process of decomposing these organic substances in the water and pond bottom produces H2S. The higher the H2S concentration, the more white foam is produced.

Ruined algae: When there are many pollutants in the pond, algae will gradually form. After a short period of time, the dead algae, also known as ruined algae, will increase the amount of pollutants in the pond. In addition, algae floating on the surface combined with fanning water will cause foam to form.

How to quickly handle white foam

When farmers notice a lot of white foam appearing in shrimp ponds, they need to come up with measures to quickly handle it to reduce the impact on shrimp health. There are 2 basic ways as follows:

* Check and adjust water quality:

Ensure water quality parameters such as pH, ammonia, nitrite, nitrate, and oxygen concentration are within safe levels for fish and shrimp. Shrimp waste levels also need to be controlled to avoid bacterial overgrowth.

1. Use beneficial microorganisms:

Add beneficial microorganisms such as nitrosomonas and nitrobacter bacteria to help improve waste management and maintain system balance.

2. Control feed amount:

Make sure you are providing the right amount of feed and not excessively. Leftover feed can increase the amount of waste in the pond.

3. Use waste treatment enzymes:

Waste treatment enzymes can help reduce the amount of organic residue in ponds, reducing the risk of bacterial growth.

4. Control light:

Reduce the amount of direct sunlight entering the pond, as sunlight can stimulate the growth of algae and bacteria.

5. Perform regular water changes:

Regular water changes help remove insoluble solids and keep the water environment clean.

6. Use water treatment methods:

Water treatment methods such as using disinfectants or water treatment agents can be applied to reduce the amount of bacteria and algae in ponds.

7. Strengthen patrols and manage expert suggestions:

Monitor and maintain follow-up on aquaculture expert recommendations to resolve incidents quickly and effectively.

-> Above is a personal opinion from TOMMY on how to handle the fan system that creates insoluble white foam in aquaculture. Farmers can refer to it for more information.

Cre: tepbac.com

Ngày đăng : 10/01/2024

1113 View

Other Articles

.jpg)