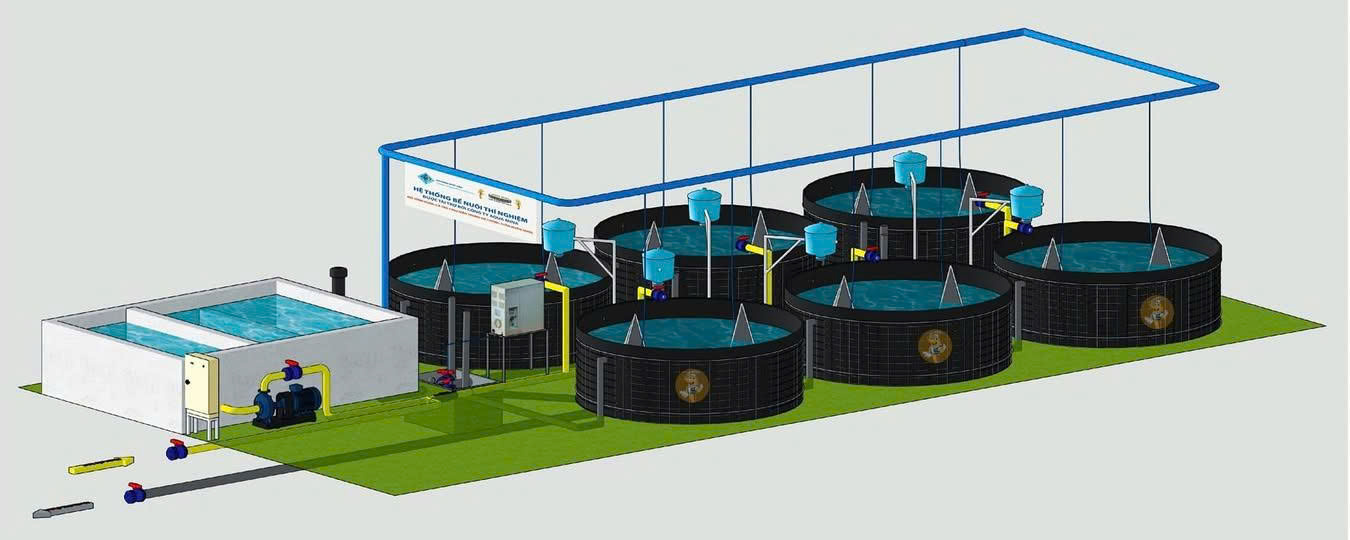

CTU-RAS: Recirculating Shrimp Farming for Sustainable Development

Advantages

Fully closed recirculating system:

The system is designed to continuously reuse water within the culture ponds, with almost no discharge to the environment. Throughout the production cycle, only about 10–20% of water needs to be added to compensate for losses due to evaporation, pumping or salinity control. As a result, the same water can be reused for up to three production cycles per year without complex treatment, reducing pressure on water resources and lowering operating costs.

Pond area allocation:

Pond areas are rationally allocated, with 70–75% dedicated to shrimp culture and 25–30% allocated to biological filtration and water-treatment zones. The filtration area is designed to remove suspended solids, sludge and part of the organic load, while suporting the growth of beneficial microorganisms, thereby maintaining stable water quality and limiting waste accumulation.

Location:

The model can be deployed either outdoors or indoors, depending on local conditions and management requirements. Indoor farming allows better control of temperature, light, rain and wind, reducing disease risks and environmental fluctuations. Outdoor farming reduces initial investment costs but requires careful attention to shading, aeration and continuous water-quality management.

Integrated multi-species system:

Co-cultured species such as tilapia and seaweed act as natural biological filters. Tilapia help remove weak or dead shrimp and disease-carrying crustaceans. Meanwhile, seaweed absorbs excess nutrients in the water such as TAN (ammonia), nitrite, nitrate and phosphate, naturally stabilizing the aquatic environment.

Feed management:

Shrimp are supplemented with natural feeds to partially replace industrial feeds, reducing FCR, enhancing flavor, color and natural shrimp quality. This approach minimizes the use of minerals and chemicals, avoids antibiotics, and ensures food safety.

System Components and Functions

Whiteleg shrimp (L. vannamei):

The main cultured species, releasing organic waste and feces that serve as nutrients for microorganisms and auxiliary species within the system.

Tilapia:

Co-cultured without supplementary feeding, primarily to control suspended solids and reduce organic waste in the water. Tilapia are not a main commercial product but play an ecological support role by converting part of the shrimp waste.

Screen filtration:

Captures suspended solids in the ponds, reduces bottom sludge and improves water quality. Prevents the accumulation of sludge and excess feed, lowering the risk of anaerobic conditions and toxic gas formation.

Biological filter media:

Provides a habitat for beneficial microorganisms that degrade organic matter and convert ammonium (NH₄⁺) → nitrite (NO₂⁻) → nitrate (NO₃⁻). Maintains nitrogen balance in the system and limits toxic effects on shrimp.

Seaweed (macroalgae):

Absorbs nitrate, ammonium and phosphorus from the water, limiting nutrient accumulation and pollution. Although not a primary product, it helps balance the environment and improve overall water quality.

AQUA MINA CO., LTD

– Address: 685 Le Duc Anh Street, Quarter 39, Binh Hung Hoa Ward, Ho Chi Minh City

– Phone: 1800 6071 (Toll-free hotline)

– Email: sales@aquamina.com.vn or oversea@aquamina.com.vn

– Aqua Mina’s Official Distributor in Japan: REX INDUSTRIES CO., LTD

– Address: 1-9-3 Hishiya-Higashi, Higashi-Osaka 578-0948, JAPAN

– Email: kimakubo@rexind.co.jp

– Phone: +81-(0)72-961-9893

– Website: www.rexind.co.jp/e/

WE WORK FOR THE SUCCESS

Ngày đăng : 20/12/2025

1248 View

Other Articles

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)