Good News: Year-Round Shrimp Farming Without Weather Impact in Cam Pha

Modern Technology and Closed-Loop Processes

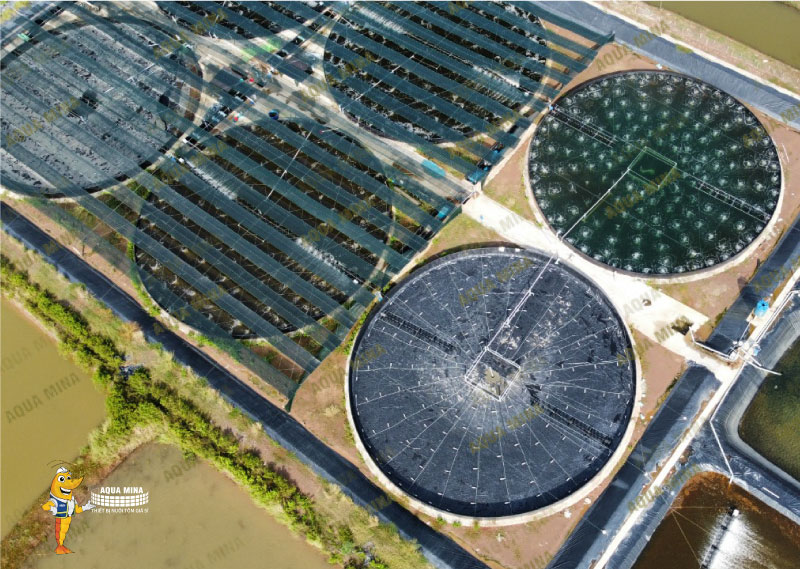

The Cam Pha High-Tech Shrimp Farming Cooperative utilizes circular concrete ponds covered with liners, enabling year-round shrimp farming unaffected by harsh weather conditions. The 6-hectare farming area includes 12 ponds and 7 water storage ponds, ensuring a closed-loop farming process from water treatment, seed stocking, feeding, to disease control. Seawater is pumped into two 2-hectare reserve ponds, undergoes preliminary water treatment, and then moves to settling ponds before being released into the farming ponds.

- Circular Concrete Ponds Covered with Liner: These ponds are constructed using reinforced concrete, are circular, and covered with liners. This design helps regulate temperature and humidity, protecting the ponds from extreme weather conditions such as heatwaves, heavy rains, and cold spells. It also minimizes rainwater intrusion that could dilute the salinity in the ponds, ensuring a stable environment for shrimp growth.

- Advanced Water Treatment System: Seawater is pumped from outside into the 2-hectare reserve ponds, passes through a raw water treatment system, then into settling ponds, and finally released into ready ponds. This process ensures that the water is always clean, meets quality standards, and is free from contamination. This system helps save on water treatment costs and maintains a consistent water source for shrimp growth.

- High-Capacity Aeration System: Aeration is continuously provided to supply oxygen for the shrimp, which is crucial for their rapid growth and reduces the risk of oxygen-related diseases. This system evenly distributes oxygen throughout the ponds, ensuring all shrimp receive the necessary oxygen levels.

- Tall, Airy Greenhouses: The greenhouses are designed to be tall and airy, unlike other shrimp farming models that often have poor ventilation. This design helps regulate temperature and humidity in the ponds, allowing year-round shrimp farming regardless of external weather conditions. The greenhouses also protect shrimp from disease-causing agents from the outside environment.

Three-Stage Shrimp Farming Process

The shrimp farming process at the Cooperative is carried out in three main stages: seed nursing, intermediate growing, and commercial farming. Each stage is closely monitored by experienced aquaculture engineers to ensure the shrimp grow healthy and reach the highest quality. The high-capacity aeration system and tall greenhouses help regulate the temperature and humidity in the ponds, creating optimal conditions for shrimp growth.

- In the seed nursing stage, shrimp larvae are released into nursing tanks, where they are nurtured in treated seawater environments. These tanks are strictly controlled for temperature, salinity, and oxygen levels to ensure healthy larval development. The nursing stage usually lasts 20 to 25 days, during which the larvae develop into healthy young shrimp.

- After the nursing stage, shrimp are transferred to intermediate ponds. Here, they continue to grow in an environment with tightly controlled environmental indicators such as salinity, temperature, and oxygen. The intermediate stage lasts 30 to 40 days, during which the shrimp grow from small young shrimp into larger commercial-sized shrimp. The aeration system and tall greenhouses ensure the shrimp receive adequate oxygen and develop under optimal conditions.

- The commercial farming stage is the final stage in the shrimp farming process, lasting 60 to 70 days. Shrimp are moved to larger ponds where they continue to grow until they reach harvest size. During this stage, they are fed high-quality feed and are closely monitored to prevent diseases. The water treatment and aeration systems continue to be maintained to ensure a stable and optimal farming environment for shrimp growth.

In early March 2024, the Cooperative started farming in 3 ponds, divided into small, medium, and mature stages. In early July 2024, the first batch of farmed shrimp was harvested, yielding over 50 tons. However, shrimp sized from 25 to 30 pieces per kg were sold at only 120,000 VND per kg, significantly lower than the average market price in previous years. At a price of 120,000 VND per kg, Mr. Đặng Bá Mạnh stated they only broke even, as many farmers from different regions were selling shrimp at the same time, leading to lower prices. Prices are expected to rise towards the Lunar New Year, making up for the lower prices now.

The Cooperative plans to expand its farming area to 100 hectares in the future, with an annual production capacity of thousands of tons of shrimp. This model has received strong support from local authorities, particularly during an inspection on June 3, 2024, when Ms. Trịnh Thị Minh Thanh, Standing Deputy Secretary of the Quảng Ninh Provincial Party Committee, expressed her approval and encouraged the model's expansion throughout the province. Ms. Thanh emphasized the importance of supporting legal procedures and creating favorable conditions for organizations and individuals wanting to invest in high-tech aquaculture.

The Cam Pha High-Tech Shrimp Farming Cooperative not only provides large shrimp yields but also creates numerous job opportunities for local residents. Currently, the Cooperative employs 35 workers, with salaries ranging from 9 to 30 million VND per month, depending on their position and duties. The first harvest demonstrated that the shrimp yield was much higher than other farming models in the area, contributing to improved income and living standards for workers.

With steady progress, the Cam Pha High-Tech Shrimp Farming Cooperative promises to continue growing strongly, contributing to economic value and environmental protection. The combination of advanced technology and a sustainable business model will be the key to achieving significant goals, not only meeting domestic consumption demands but also aiming for exports, bringing the Cam Pha shrimp brand to international markets. The Cam Pha High-Tech Shrimp Farming Cooperative truly demonstrates that applying technology to agriculture can yield impressive results, providing a solid foundation for the sustainable development of Vietnam's aquaculture industry.

Source: tongcucthuysan

Ngày đăng : 03/09/2024

2017 View

Other Articles

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)