OXYGEN REQUIREMENTS FOR WHITELEG SHRIMP AND RELATED ISSUES

Sources of dissolved oxygen in shrimp ponds include the photosynthesis of algae during the daytime under sunlight. A series of chemical reactions occur, ultimately producing oxygen for the pond. On sunny days, between 8 a.m. and 4 p.m., the DO level inthe pond often reaches ≥ 7 mg/l. Paddle wheels help promote oxygen diffusion from the air into the water, providing additional oxygen. Aerators and oxygen injectors deliver oxygen directly into the water.

Oxygen levels may decrease due to various reasons. Algae respire at night, consuming oxygen and releasing CO₂. Oxygen levels typically drop starting at 5–6 p.m. and reach the lowest point between 1 a.m. and 6 a.m. On cloudy or rainy days, limited sunlight restricts photosynthesis, reducing oxygen supply. Low alkalinity (≤ 60 mg/l) also leads to lower DO levels. Harmful gases like NH₃ and NO₂, when exceeding safe limits, restrict oxygen diffusion into the pond. Hot weather increases water temperature, limiting oxygen solubility. High salinity reduces DO because dissolved minerals and metals hinder oxygen solubility.

Excess feed, shrimp waste, molted shells, dead shrimp, and decomposing algae accumulate at the pond bottom, leading to organic decomposition and toxic gas production. These processes consume large amounts of oxygen, leading to oxygen depletion.

Shrimp lacking oxygen tend to rise to the surface or congregate along pond edges, especially in the early morning or evening. Symptoms include reduced or no feeding, difficulty molting, soft shells, pink gills and body, muscle damage, and mortality. Elevated NO₂ levels cause it to bind with hemocyanin in shrimp blood to form methemoglobin, reducing oxygen-carrying capacity. Pond bottoms may turn black and foul-smelling. Bubbles form, dark and hard to burst, with viscous and smelly water, all indicating oxygen depletion. Shrimp tend to gather around aeration points. DO levels falling below ≤ 4 mg/l and rising NO₂ levels pose a serious threat.

Shrimp feeding behavior declines. Molting becomes difficult; shells remain soft for long periods. Growth slows or halts, and mortality occurs at pond bottoms or near siphon pits. Weakened shrimp are more vulnerable to disease outbreaks, which compromise health, growth, immunity, and disease resistance.

Maintaining stable algae populations with green or brownish water color is essential. Dominant species include Chlorella (green algae) and diatoms like Chaetoceros sp. and Skeletonema sp. Algae help purify water, absorb toxic gases, limit organic decomposition, suppress harmful bottom vegetation, and generate oxygen. Daily feed management should prevent excess. Siphoning the pond bottom regularly removes waste and molts. Aeration should be increased to improve oxygen levels. Shrimp stocking density must match the farming model and be supported by proper equipment. Regular water exchange from ready sources helps improve DO levels.

Ventek Nano Bubble Oxygen Combined with Fresh Oxygen Generator – The Best Solution for Ultra-Fine Oxygenation Today

Ventek Nano Bubble Oxygen helps reduce capital and operational costs, ensuring long-term use and lowering production expenses.

Initial investment cost is only 50%, and operating cost is 20% compared to traditional bottom aeration systems. It completely replaces bottom aeration pipes, saving labor on cleaning after each crop. No more fungal build-up on plastic legs and pipes. Cleaner pond bottoms, easier operation, and labor savings.

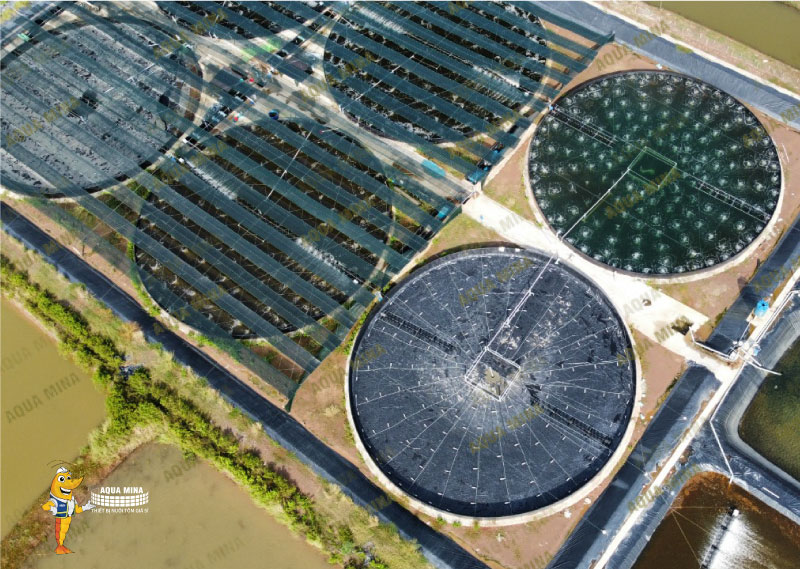

Verified Field Results at Aqua Mina Show High DO Levels When Using Ventek

Ventek makes it easier to grow shrimp to larger sizes.

Especially effective during the final stage of the crop when supplemental oxygen is needed to push shrimp to larger sizes. Larger shrimp fetch higher prices and improve farm profits.

Ventek Nano Bubble Oxygen is available in three flow rates: 100L/min, 300L/min, 500L/min

Advantages of the Ventek Nano Bubble Oxygen:

Innovative Technology: Spiral mixing technology enhances oxygen dissolution more efficiently than other products on the market. This patented innovation was developed by HueTronics JSC.

High-Quality Materials: Made from POM (Polyoxymethylene), a plastic known for thermal stability, mechanical strength, wear resistance, lightweight, and seawater durability. The air inlet is made from 316 stainless steel, ensuring resistance to seawater corrosion. The product includes a 36-month manufacturer’s warranty.

Wide Range of Flow Capacities: From 100 to 500 L/min, suitable for nursery ponds (100m²) to grow-out ponds (up to 2,000m²). Offers flexible options tailored to different pond sizes for optimal performance.

Compatible with Most Pumps: Designed for centrifugal pumps with a head pressure of 13–15m. Pump flow rates should match the model.

Designed and manufactured by HueTronics JSC. The product has been researched and field-tested for over 5 years at shrimp farms in Hue, Can Gio, Soc Trang, and across Vietnam, delivering consistently high performance.

AQUA MINA is the exclusive distributor of the Ventek Nano Bubble Oxygen, designed and manufactured by HueTronics.

Ventek generates ultra-fine oxygen bubbles (1.6 microns), improving oxygen uptake in shrimp.

Ventek Installation Guide Available.

Aqua Mina's distributor in Japan: REX INDUSTRIES CO., LTD

- Address: 1-9-3 Hishiya-Higashi, Higashi-Osaka 578-0948 JAPAN

- Email: kimakubo@rexind.co.jp

- Phone: +81-(0)72-961-9893

- Website: http://www.rexind.co.jp/e/

WE WORK FOR YOUR SUCCESS!

Ngày đăng : 04/08/2025

2460 View

Other Articles

Indian shrimp pivot to the EU, increasing competitive pressure on Vietnam

Indoor shrimp farming in Europe: Investment challenges and the race to find a viable model

Shrimp production surged in the first month of the year, with exports benefiting from strong demand during the Lunar New Year holiday

Quang Ninh Accelerates Digital Transformation in Shrimp Farming, Rising to Lead Northern Vietnam

Lucky money is not just about cash — it’s Aqua Mina’s wish for a worry-free farming season for our valued customers

Việt Nam's top 10 seafood exporters command nearly one-fifth of industry revenue

Ca Mau Maintains Its Shrimp Brand in International Competition

VIETSHRIMP ASIA 2026 & AQUACULTURE VIETNAM 2026 – A TURNING POINT FOR THE MODERN SHRIMP FARMING INDUSTRY

Ecuador's shrimp industry educational program SustainED kicked off its 2026

An Giang will start raising brackish water shrimp as early as the beginning of 2026

Aqua Mina conducts the on-site installation of two aquaculture air blowers | Ceramic Ball Bearing – 15 kW – 25 kPa for a customer in Quang Ninh

Towards Building Brand Value for the Shrimp Industry

.jpg)